Concrete is an incredibly versatile material that has been used in construction for centuries. One of the most popular forms of concrete used in modern construction is precast concrete. Precast concrete is produced in a factory and then transported to a construction site, where it is installed. This method of construction has become increasingly popular in recent years due to its many advantages. Keep reading on to learn what is precast concrete and its uses.

What is Precast Concrete?

Precast concrete is manufactured off-site in a controlled environment. It is cast in reusable moulds for more flexibility in shapes and finishes. The concrete mix is precisely formulated for strength and durability. After casting, the concrete undergo a curing process for hardening. Then, they are transported and installed on-site. This method improves quality control, speeds up construction and reduces on-site labour.

Build your home using precast concrete and technical assistance from JK Cement BuildXpert. Connect with us now!

What Are the Different Types of Precast Concrete?

Precast concrete comes in various types, each designed to meet specific construction needs:

Precast Concrete Foundation

Precast concrete foundations are utilised to support structures such as buildings or bridges. These foundations are manufactured off-site in controlled conditions. The purchaser provides details related to the required consistent compressive strength, dimension and more to ensure desirable quality and strength. They come in various shapes and sizes to accommodate different structural requirements and soil conditions.

Precast Concrete Staircase

Precast concrete staircases are preassembled stair units that are fabricated off-site and then transported to the construction site for installation. These units consist of individual steps, landings and supports cast together as a single piece.

Precast Lintel and Chajjas

Precast concrete lintels and chajjas (cantilevered projections) are structural parts used to support openings such as doors and windows in buildings. Lintels are horizontal beams placed above openings to bear the load from the structure above, while chajjas provide shade and protection.

Precast Planks and Joists for Flooring and Roofing

Precast concrete planks and joists are prefabricated components used in flooring and roofing systems. These elements are designed to span between supports to provide a stable platform for floors and roofs. Precast planks and joists are manufactured with high-strength concrete and reinforced with steel to withstand loads and ensure structural stability.

Precast Concrete Beams and Columns

Precast concrete beams and columns are structural elements used to support vertical loads in buildings and other structures. These are commonly used in the construction of bridges, parking structures and building frames to support heavy loads and provide long-lasting performance.

Uses of Precast Concrete

Common uses of precast concrete are as follows:

Building Construction:

Precast concrete elements like beams, columns, walls and floor panels are widely employed in the construction of residential, commercial and industrial buildings.

Infrastructure Projects:

In infrastructure development, precast concrete is utilised for bridges, tunnels, retaining walls and culverts.

Water Management Structures:

Precast concrete products can be used to construct structures for storing water and other fluids. Common examples include manholes, septic tanks, pipes, stormwater detention systems and sewage treatment.

Landscaping:

Precast concrete is utilised for various landscaping and hardscaping features like retaining walls, pavers, steps and decorative elements.

How to Source High-Quality Precast Concrete Products?

Sourcing high-quality precast concrete products is crucial for ensuring the success and durability of construction projects. Here are key steps to consider:

1. Research and Selection:

Research reputable precast concrete manufacturers. Consider factors such as experience, Bureau of Indian Standards (BIS) certifications and customer reviews to make an informed choice.

2. Quality Assurance:

Verify that the manufacturer follows stringent quality control processes throughout the production cycle. This includes using quality materials, adhering to industry standards and conducting thorough inspections to ensure product integrity.

3. Customisation and Design Support:

Choose a supplier that offers customisation options and technical support to meet your specific project requirements.

4. Production Facilities:

If possible, consider visiting the manufacturer’s production facilities to assess their capabilities, equipment and manufacturing processes firsthand.

5. Consider Logistics and Delivery:

Evaluate the supplier’s logistics capabilities, including transportation, handling and on-site delivery services.

Wrapping It Up

Precast concrete is a versatile and efficient material in the construction industry. Its various benefits, such as cost-effectiveness, durability and sustainability, make it an attractive option for many construction projects. It can be a more sustainable and resilient option for various innovative and environmentally friendly construction projects.

Ready to build your home with strong cement? Discover the superior quality and durability of JK Cement’s range of various types of cement.

FAQs

What is precast concrete used for?

Precast concrete is used in construction applications including, building components like beams, columns, walls and floor panels.

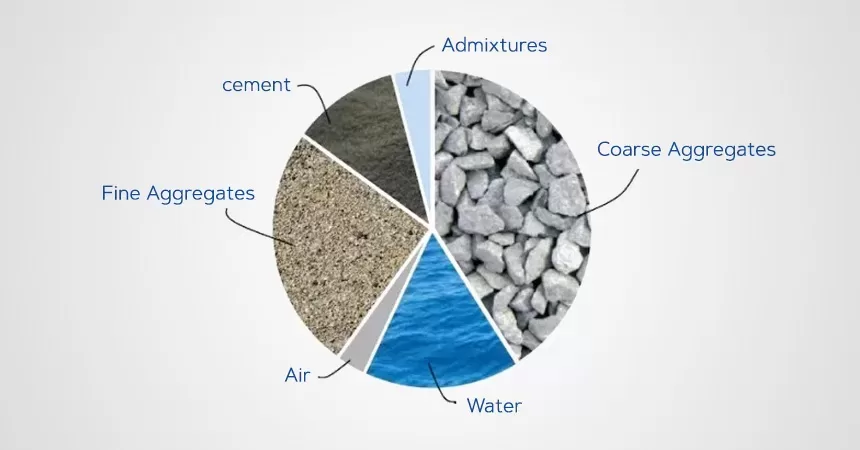

What material is used for precast concrete?

The primary materials used for precast concrete are reinforcement (steel bars), cement, aggregates (sand, gravel or crushed stone), water and admixtures.

What is the aim of precast concrete?

Precast concrete aims to provide durable, high-quality construction components manufactured off-site in controlled conditions.

What is also known as precast concrete?

Precast concrete is also known as prefabricated concrete.

How strong is precast concrete?

Precast concrete can vary in strength depending on the mix design, reinforcement and production methods used. Generally, precast concrete offers high strength and durability, with compressive strengths typically ranging from 25 MPa to 50 MPa or higher.