Cement is an ingredient of concrete which is an essential construction material. Limestone and clay obtained from quarries are processed to form cement. Portland cement is the most widely used cement for construction. Depending on your construction needs, Portland cement can be of numerous types, out of which Portland Pozzolana Cement is used for almost all construction projects. You can find information on PPC below.

What is PPC in Cement?

The full form of PPC in cement is Portland Pozzolana Cement. PPC is a type of blended cement comprising Portland clinker, pozzolana particles and gypsum in certain specific proportions. Clinker are pebble-sized particles formed by intimately grounding limestone and clay and heating it in kilns at high temperatures. When clinker is blended with gypsum, it forms Ordinary Blended Cement (OPC), when OPC is blended with natural or artificial pozzolana particles.

What is Pozzolana?

Pozzolana or pozzolans are particles that contain constituents which when combined with lime and water forms compounds that possess cementing properties. Pozzolana can be of the following types:

-

Natural Pozzolana:

Natural pozzolana is calcined materials with pozzolanic properties. These include volcanic ash, pumicite, shales, clay, diatomaceous earth, etc. -

Artificial Pozzolana:

Artificial pozzolanic materials include burnt clay, silica fume, fly ash produced from coal-fired power plants, blast furnace slag, etc.

Types of Portland Pozzolana Cement

Based on the type of pozzolana used, PPC can be categorised into the following:

-

Fly Ash-based PPC:

In this type, artificial pozzolanic materials are blended with Portland clinker with the addition of gypsum. The fly ash-based PPC must conform to Indian Standard 3812. -

Calcine Clay-based PPC:

As the name suggests, in this type of PPC, pozzolana that is sourced naturally is blended to form PPC.

How is PPC Made?

The following is the manufacturing process of PPC:

- Materials comprising lime, silica, alumina and iron oxide are intimately grounded.

- This mix is heated at extremely high temperatures in a kiln to form Portland clinker.

- Portland clinker is further ground with fly ash or calcined clay or Portland cement is uniformly blended with the pozzolana particles. The pozzolana constituent should be in the range of 10 to 25% by mass of PPC.

- Natural or chemical gypsum may be added during the grinding process.

Applications of PPC

PPC can be used in the following constructions:

- PPC is widely used in hydraulic structures like dams that are submerged fully or partially in water to disrupt the natural flow of water.

- PPC is also effective for marine structures like piers, wharfs, bridges, etc. erected in sea water.

- It can be used to form pre-stressed or post-tensioned concrete members

- You can use PPC effectively in masonry and plasterwork as well.

- PPC offers a superior surface finish, making it ideal for decorative structures.

- PPC is also suitable for developing precast sewage pipes.

Properties of Portland Pozzolana Cement2 3

Per the Bureau of Indian Standards (BIS), PPC should possess the following properties:

-

Fineness

It indicates the particle size of cement which impacts the surface area and, in turn, the heat of hydration. The surface of PPC must be at least 300m2/kg.

-

Soundness

Using the Le Chatelier method, unaerated Portland Pozzolana Cement shall not have an expansion of more than 10 mm and 0.8%, respectively. Soundness of cement is the volume change when its set and hardened.

-

Initial Setting Time

The initial time is the time when cement turns into paste when mixed with water and begins losing its plasticity. For PPC, the initial setting time is 30 minutes (minimum).

-

Final Setting Time

The time when cement loses its plasticity completely after it has been mixed water is the final setting time. The final setting time for PPC is 600 minutes (maximum)

-

Compressive Strength

Compressive strength refers to the capacity of concrete to withstand load without cracking or deflecting. The compressive strength of concrete at 3, 7 and 28 days should be 16MPa, 22MPa, and 33MPa, respectively.

-

Drying Shrinkage

Drying shrinkage is the contracting of hardened concrete due to the loss of capillary water. The percentage of drying shrinkage should not exceed 0.15%.

Benefits of PPC

Here are the advantages of Portland Pozzolana Cement:

- PPC is an environment friendly cement since it uses recycle waste products (for instance, fly ash) in its production.

- When water is added to PPC, it forms a reaction with lime and alkalies present in cement. This reaction provides strength to concrete.

- PPC also contributes to better workability, reduces bleeding and minimises leaching of free lime.

- PPCs have a low heat of hydration which help minise the incidence of cracks in the concrete.

- Inexpensive constituents make PPC an economical construction material.

- Its resistant to sulphate attacks makes PPC an ideal construction material for hydraulic and marine structures.

- Portland Pozzolana Cement also prevents permeation of harmful salts and gases which facilitates corrosion-free reinforcements.

- The fine pozzolana materials can fill the voids caused by aggregates and subsequently minimise the shrinkage of concrete when its dry.

Avail of high-strength and durable buildings with JK Super Cement – PPC.

FAQs

How should PPC cement be stored?

PPC cement should be stored in weather-proof buildings to prevent the cement from dampness and minimise potential warehouse deterioration. Additionally, it must be stored in a way that allows easy access for inspection and identification.

What is the difference between OPC, PPC and PSC?

When Portland cement clinker is ground with gypsum, it produces Ordinary Portland Cement (OPC). When the clinker is ground with pozzolana, it creates PPC. Similarly, when the clinker is ground with slag, it produces PSC. PPC and PSC are blended cements that provide improved properties to the concrete mix.

What is the role of gypsum in cement?

Gypsum is added to cement as it controls the setting time of concrete.

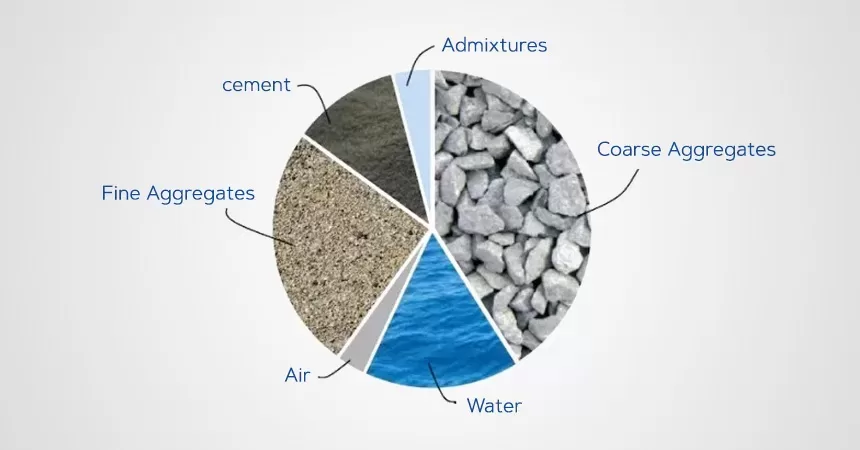

How is concrete made?

Concrete is made by mixing cement, aggregates and water in the required proportions. Different grades of concrete will have different concrete mix ratios.

Why is water necessary in concrete?

When it comes to concrete, the aggregates, i.e., sand, gravel or crushed rocks need a substance that will bind them and form a durable structure. The binding is provided by cement when it’s mixed with water. Water hydrates the cement and causes the concrete to harden through a chemical reaction called hydration.

What are the grades of concrete?

The grade of concrete is its compressive strength at 28 days. The following are the different grades of concrete:

| Group | Grade Designation | Specified Characteristic Compressive Strength of 150 mm Cube at 28 Days |

| Ordinary Concrete | M10 | 10 N/mm2 |

| M15 | 15 N/mm2 | |

| M20 | 20 N/mm2 | |

| Standard Concrete | M25 | 25 N/mm2 |

| M30 | 30 N/mm2 | |

| M35 | 35 N/mm2 | |

| M40 | 40 N/mm2 | |

| M45 | 45 N/mm2 | |

| M50 | 50 N/mm2 | |

| M55 | 55 N/mm2 | |

| High Strength Concrete | M60 | 60 N/mm2 |

| M65 | 65 N/mm2 | |

| M70 | 70 N/mm2 | |

| M75 | 75 N/mm2 | |

| M80 | 80 N/mm2 |

*Disclaimer: The information provided above is for general purpose and should not be used as a substitute for professional advice.