Our Manufacturing Plants

Manufacturing Process

At JK White Cement Works, Gotan, we use technical expertise from F.L. Smidth & Co. from Denmark and state-of-the-art technology with continuous on-line quality control by micro processors and X-rays to ensure that only the purest White Cement is produced. We manufacture White Portland Cement through these 5 significant stages – crushing, raw meal grinding, clinkerisation, cement grinding and packing for dispatch.

- At the raw mill, crushed limestone, clays and feldspar of desired chemical compositions are fed through electronic weigh feeders.

- Clinkerisation is the heart of cement manufacturing process, where the raw material is fed to a pre-heater at a controlled rate through an electronic weigh feeder. The feed enters the kiln through cyclones and fuel is fired at the kiln outlet end.

- Clinker and gypsum are fed to the cement mills through electronic weigh feeders at controlled rate and ground in ball mills. The classifier (high efficiency separator) controls the fineness of white cement. The finished product of desired chemical composition and physical properties is transported to Cement Silos for storage.

- White cement is drawn from cement silos, for packing in bags by electronic rotary packer and in small pouches by Fill, Form and Seal machines.

Plant Quality Focus

At JK Cement, quality is not just a product centric vision but an Omni-organisational vision. With a firm belief that quality begins and ends with people, the management has inculcated a quality culture in the very thought process of the organisation.

JK Cement Works - Nimbahera & Mangrol

JK Cement has effectively pledged its reputation as the market leader in quality of cement manufactured. At Nimbahera and Mangrol, our labs are equipped with State-of-the-art Process control instrumentation and quality control system. The testing laboratory is manned by qualified personnel to ensure quality of product comparable to the best available in the market at all times. The quality management system at JK Cement Works is certified by the Prestigeous Lloyds Register for quality assurance since the year 1995

Our plants are also ISO 9001:2008 & ISO 14001:2004 certified and are in the process of getting our laboratory accredited with the NABL-National Accreditation Board for Testing and Calibration Laboratories.

JK Cement Works - Muddapur

JK Cement Works, Muddapur is equipped with high efficiency dust filtration systems, which are installed for the main manufacturing process as well as at various transfer points to avoid dust emission to the atmosphere. Thus the plant has latest technologies, process control as well as quality control for plant operation with Robo lab and Automatic Blain Analyser. The entire plant is controlled from Central Control Room (CCR) with sophisticated control systems of latest technologies including Fuzzy Operations.

JK Cement Works - Gotan

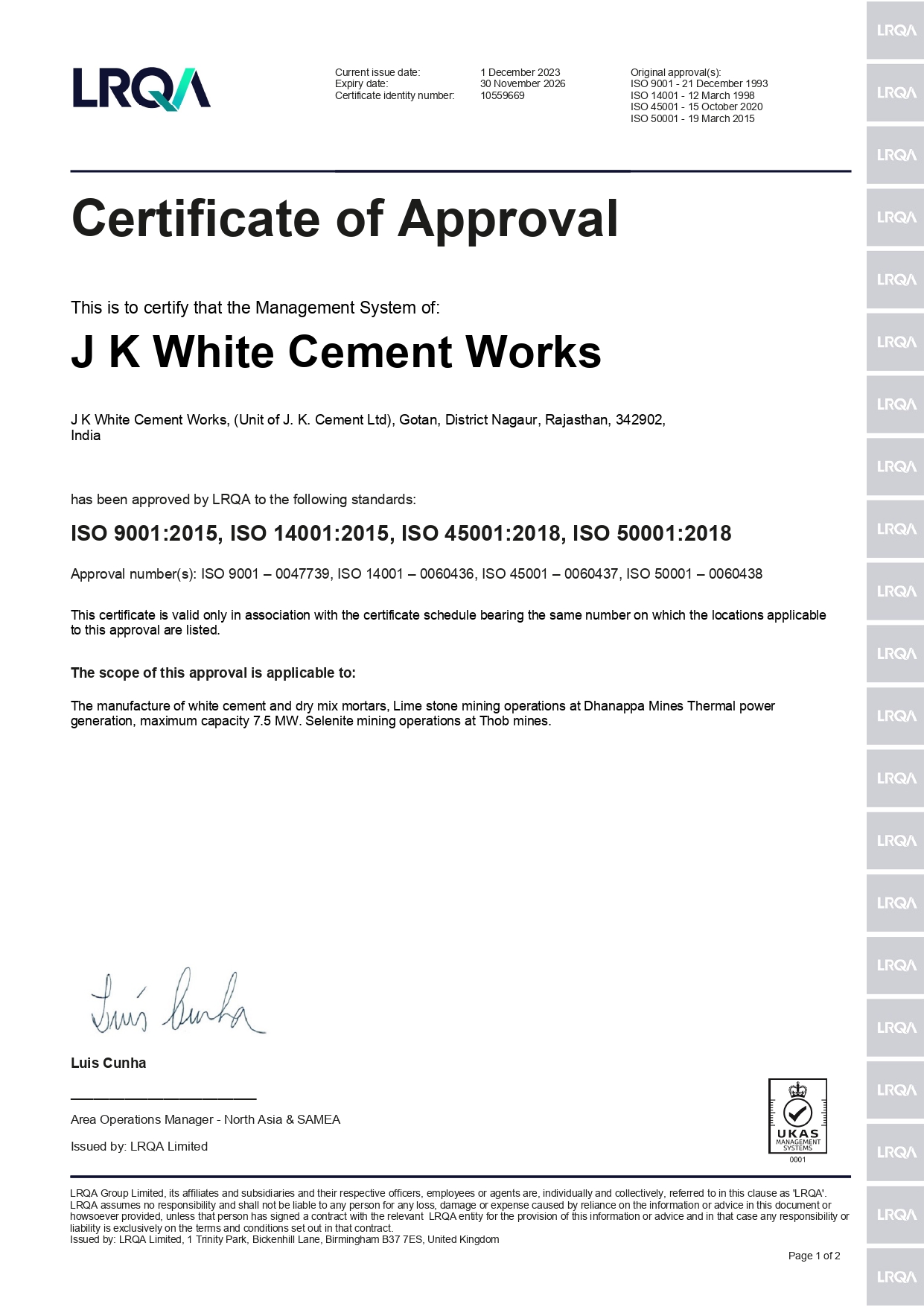

In keeping with the vision of international quality standards, the Quality Management System (QMS) of JK White Cement Works, Gotan has been certified by the prestigious Lloyds Register for Quality Assurance since the year 1993. It was not only one of the few Cement plants which was certified with ISO 9001, but also among the very few whose Marketing department is also included in the scope of certification.

The Plant has now been certified with the latest revised standard of ISO 9001. Besides, the plant is also accredited with OHSAS 18001 ISO 14001 and Social Accountability 8000 certification, all of which go on to make it one of the most comprehensive, holistic quality management endeavours in the category.

Certifications

At JK Cement, our quality parameters have been verified by various certification bodies. All our units are certified with Quality Management System and Environmental Management System as per ISO 9001 and 14001. The Certification Agency is Lloyds Register Quality Assurance Limited. Besides the above, our White Cement plant is also certified for OHSAS 18001 and SA8000. JK White Cement carries the CE Mark (Mark of European Conformity as per European Construction Products Directive)