Wall Putty

What is Wall Putty?

Giving your home a stunning makeover is essential for leaving an everlasting impression on the people around you. Experimenting with the colour wheel and creating textures on the walls of your home can add to uplift the cheerful feeling within us. That said, while painting is the best alternative to enhance the aesthetics of your home decor, integrating wall putty in your home refurbishing essentials ensures that their beauty prolongs.

Wall putty, white cement-based fine powder, lays down a strong foundation for the paint by offering an even and smooth surface to paint over. It is made with additional polymers and other minerals, which contribute to the velvety smoothness of painted walls.

Furthermore, it ensures that the painted surfaces of your home give out the first-day appearance throughout the year. Wall putty adds a layer of defence to them against moisture intrusion, efflorescence, and the growth of mould, to create a flawless surface in the exterior and interior of your home.

Wall putties are regarded as quite a versatile material as they can be applied to any wall, from rendered, concrete, to precast walls. They provide absolute whiteness enhancing the overall appearance of the walls.

Range of Wall Putty

Benefits of Wall Putty

Highly Versatile

Wall putty can be applied to both interior and exterior walls for a variety of purposes.

Paint Durability

Wall putty enhances the life of the paint on the walls. It is suitable for all types of paint and produces a beautiful finish.

Excellent Binding

Wall putty binds strongly with the base. In fact, it improves the strength of the surface.

Damage Protection

It protects the wall from factors like crack formation, efflorescence, flaking, mould formation, and much more.

Sheen Finish

Wall putty offers a smooth, glossy finish and imparts a sparkling whiteness to the applied surface.

How to Apply Wall Putty

Step1- Surface Preparation

Clean the surface thoroughly. It is essential to free the surface prior to wall putty application from oil, solvents, dirt and dust.

Step 2- Mixing

Mixing with a mechanical stirrer is recommended to make a homogenous and lump-free paste. JKCement wall putty and its variants should be mixed slowly to form a smooth, and homogenous paste. Wait for 5 minutes before applying the paste. Furthermore, the prepared paste should be applied within 2-3 hours.

Step 3- Pre-wetting the wall

Before wall putty application, pre-wet the wall surface to remove loose dust particles.

Step 4- Application

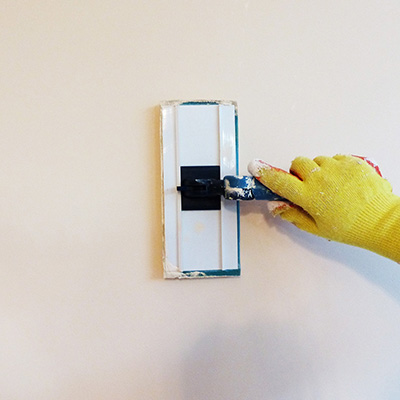

Using a spatula/ blade/ trowel, apply the first coat of the homogenous paste from the bottom to the top and the second coat horizontally.

Step 5- Second coat

Once the first coat dries, clean the surface to remove loose particles with a sponge/ cloth/ putty blade before the second coat application.

Step 6- Drying

Before the application of distemper or paint for a premium look, wait for the surface to dry completely.

Wall Putty Features

Areas of Application

FAQs

Wall putty is used for the following reasons:

- Smooth Surface for Painting

Wall putty has an excellent bonding property which protects the walls from the ill effects of abrasion and can help in creating a smooth surface by covering all the undulations, for a beautiful paint finish. - Increases paint life

Wall putties have superior adhesion and tensile strength. When they are applied to the walls, they provide resistance against dampness, flaking, etc., thus increasing the paint life of the walls by protecting their beauty for a longer period of time. - Multi-purpose Application

It can be used on interior and exterior surfaces, dry or wet walls, or new walls for a blemish-free surface.

Wall putty and white cement are not the same. But, they are related to each other as most wall putties are white-cement based. Apart from this, wall putties are used for filling pin holes, whereas white cement is used for repairing marble tiles and sheathing roofs, walls, ceilings, etc.

The best putty for walls is JKCement’s MaxX range of wall putties. They prevent mould formation and resist efflorescence. Furthermore, these putties also ensure that the interior and exterior walls of one’s home are always smooth and glossy.

There are certain variants of wall putties, such as JKCement ShieldMaxX which is damp-resistant and suitable for application on exterior walls.

The application of primer is optional, however, in the case of white cement-based putties such as the JKCement MaxX range of wall putties, primer should be applied only after putty application.

Yes, it is necessary to apply putty before painting as it is essential for the increased paint life of the wall paint. Additionally, it equips the walls with a protective layer against abrasion, moisture, and efflorescence and levels the undulations for a smooth wall surface prior to painting.

For the wall putty to completely dry, it takes 4-6 hours.

- Ensure the wall is completely clean before putty application.

- Always mix water and putty in the right ratio as per the manufacturer’s instructions. The mixture should be smooth and lump-free.

- Mix the putty homogenously with a mechanical stirrer.

The right way to apply putty is:

- Clean the surface thoroughly prior to putty application.

- Create the putty paste by mixing putty with 38-42% water with a mechanical stirrer.

- Before putty application, pre-wet the wall surface.

- Apply the first coat of putty with a spatula or blade from bottom to top and the second horizontally.

- After first coat dries, clean the surface with a sponge and then apply the second coat of putty.

- Let the surface dry completely.

- It has a multi-purpose application.

- Superior tensile and compressive strength.

- Makes the walls abrasion resistant

- Excellent workability

- Suitable for all types of paint.

- Makes the walls smooth and glossy.

- Increases the paint life.

- Provides resistance against fungi, mould, moisture, etc.

- Levels out all kinds of undulations.

- Fills in pin holes on walls.